FÖRSTER manipulators position small or large, light or heavy workpieces steplessly on multiple axes.

Demanding assemblies with different welding positions can be machined in the correct position and in an ergonomic working position in one clamping.

We adapt component-specific payload and equipment features as well as optional versions of the table surfaces to customer-specific requirements.

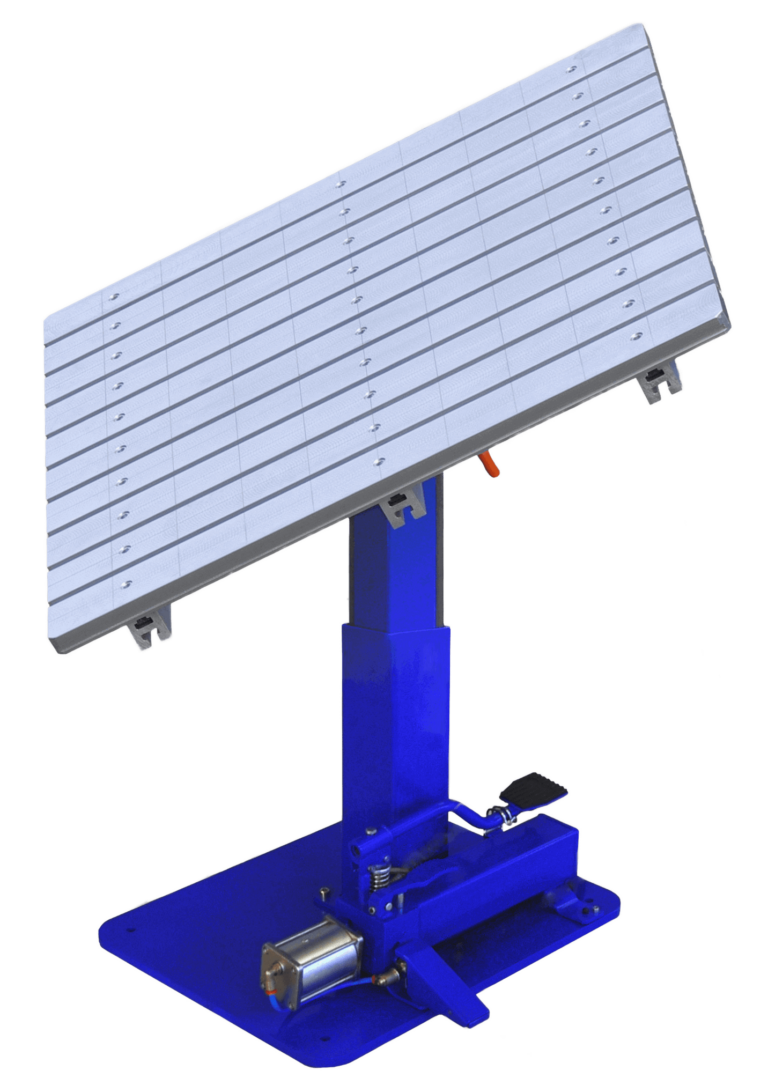

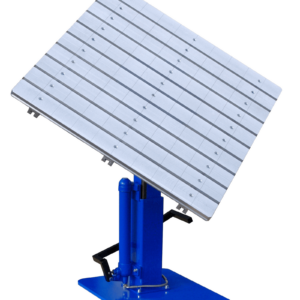

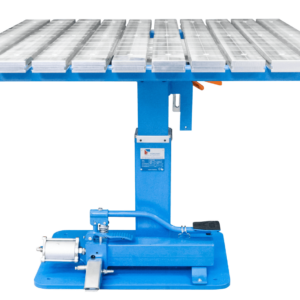

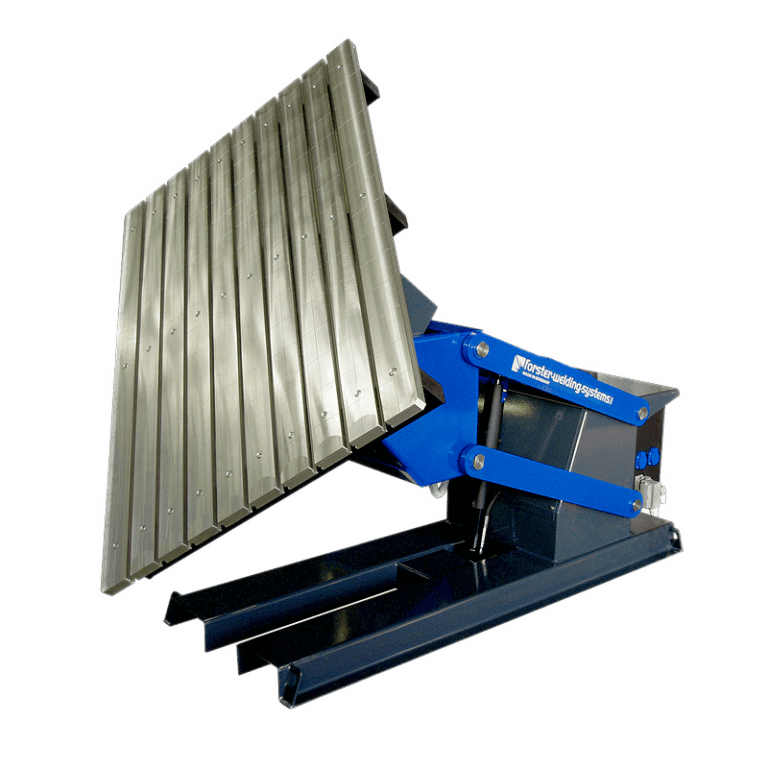

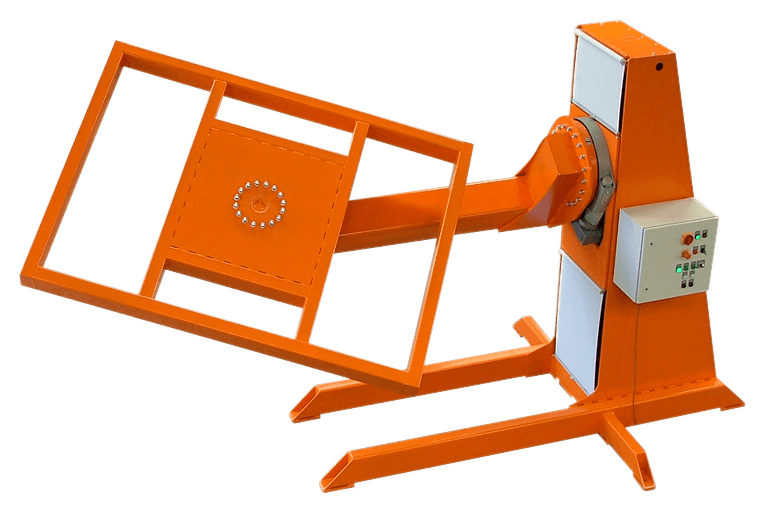

ERGOFIX Manipulator

Hight adjustable weld and assembly table with rotary and tilt function

With our own development, the Ergofix manipulator, work steps are made considerably easier. The manipulator is a height-adjustable table with a hydraulic stroke of 690 to 990 mm, it can be manually tilted up to 45° and rotated 360° in any position.

This means: Working in an ergonomically favorable position and the best possible seam position for very good welding results.

- Table top height from 690 – 990 mm

- Rotate 360° endless (locking with clamping lever)

- Tilting angle stepless from 0° to 45° (locking with clamping lever)

- Payload up to 150 kg

- Table surface can be fitted with rails in Al/Cu alloy / gray cast iron / X-PRO profile / double-groove profile

Request a non-binding offer for ERGOFIX manipulator

for welding by hand

For light or heavy components with many different welding positions, manipulators are the solution for quality and high-quality welds executed in an ergonomic position.

The infinitely variable positioning of the workpiece takes place via three independently controllable axes. A handy remote control enables all movements to be controlled and the component rotation can be operated via a foot pedal.

FÖRSTER manipulators and positioners are available in a variety of designs and ensure synchronization even with asymmetrical clamping.

Advantages of positioners and manipulators

- increase in quality

- Increase in occupational safety

- Improvement of work ergonomics

- Increase in productivity through an optimal working position

- Table surface height from 644 mm – 2552 mm

- Rotate 360° endlessly

- Continuous tilting angle of up to 155°

- Payload up to 20 t

- Table surface can be fitted with rails in Al/Cu alloy / gray cast iron / X-PRO profile / double-groove profile

Request a non-binding offer for positioners

Manipulators and positioners in connection with robot systems are integrated directly or indirectly into the robot control as additional movement axes.

This enables a synchronized movement with the robot, which forms the basis for perfect processing quality.

The weight of the component and the position of the component’s center of gravity are primarily decisive for the selection of a suitable manipulator. In addition to these two criteria, we incorporate further customer-specific requirements into the design in order to be able to offer you the ideal manipulator.

For your robotic welding solutions we manufacture:

- single-axis positioner

- Single-axis positioner with counter bearing

- two-axis positioner

- multi-axis positioner

Do you have special requests, e.g. heavier loads, larger dimensions or do you need more information? No problem! Contact us here.