FÖRSTER welding tables have been proving their robustness and durability for more than 30 years.

By combining the well-established concept of the T-slot from machine tools with the special gray cast iron rails as the surface, we manufacture a unique welding table in-house.

Thanks to variability and robustness, our welding tables provide the perfect basis for any of your future welding tasks.

Fast, dimensionally accurate and angular clamping as well as the reduction of cleaning work drastically reduce your non-productive times.

Welding tables

Modular design and robust surface

- The table can be expanded and is ideal for all types of assembly and welding work, including heavy steel construction.

- The rails of the table surface can be removed individually and thus enable the size of the table surface to be adjusted by partial occupancy.

- The solid material forgives scratches, impacts and other damage – the weld spatter protection is retained!!!

Low cost of accessories = maximum freedom

- With our self-developed clamping system and stop elements, you can work precisely, dimensionally and angle-accurate WITHOUT the grid requirement.

- The multi-functionality of our building blocks gives you the opportunity to achieve a lot with just a few accessories, to combine existing accessories with each other and to use third-party tools.

- point loads up to 1,5 t,

- surface loads up to 3,0 t

- surface flatness +/- 0,05 mm

- other variants on request

FAQ

FÖRSTER welding tables are characterized, among other things, by their longevity.

Even under the toughest operating conditions, the weld spatter-repellent properties of our gray cast iron table surface remain intact for many years. The older a FÖRSTER welding table gets, the less maintenance it requires.

This means no loss of properties = permanent protection against weld spatter buildup.

FÖRSTER welding tables are robust and torsion-resistant assembly and welding tables on which you can assemble, hammer, grind and of course weld.

…you can find out more about this under technologies.

On a FÖRSTER welding table, the rails from the table surface can be removed individually, thus opening the table surface. This means that components can be inserted into the “minus z” and laid flat at the same time, without costly extensions.

A FÖRSTER welding table offers you maximum flexibility and actual work in 3 dimensions, including “minus Z”.

You can find out more about this under technologies or experience our entrance animation.

When clamping, focus on the component and not on the table’s hole grid.

Simply place your assembly on the table and move your stop, clamping and support elements into position in an infinitely variable manner, just as your component specifies.

By continuously moving the sliding block and adjusting the range of the clamping device or stop element, you can reach every point on the table.

And thanks to our rhombus slot block, you can also insert clamping devices and stop elements into existing grooves. …you can find out more about this under technologies.

Our range of accessories is well thought out, universally applicable, easy to overview and intuitive to understand.

FÖRSTER clamping devices and sling elements are designed so that they can be used in various functions and can be easily combined with other clamping and slinging devices.

The range includes just over 30 parts with which you can cover almost every welding task. FÖRSTER offers you a compact modular system of clamping devices and stop elements that can be combined or interchanged with one another.

Our groove system also offers the advantage that you can use self-made stop elements (e.g. special shapes) on our table.

You can simply continue to use existing accessories for hole systems thanks to our adapters.

Our welding tables are manufactured and assembled at our company headquarters in Hohenstein-Ernstthal.

We also cut, CNC machine, refine and assemble the surface in-house. The same applies to the table base, which is welded and painted in-house.

Accordingly, we can implement customer requests individually.

Made in Germany

Request a non-binding quote for standard welding table

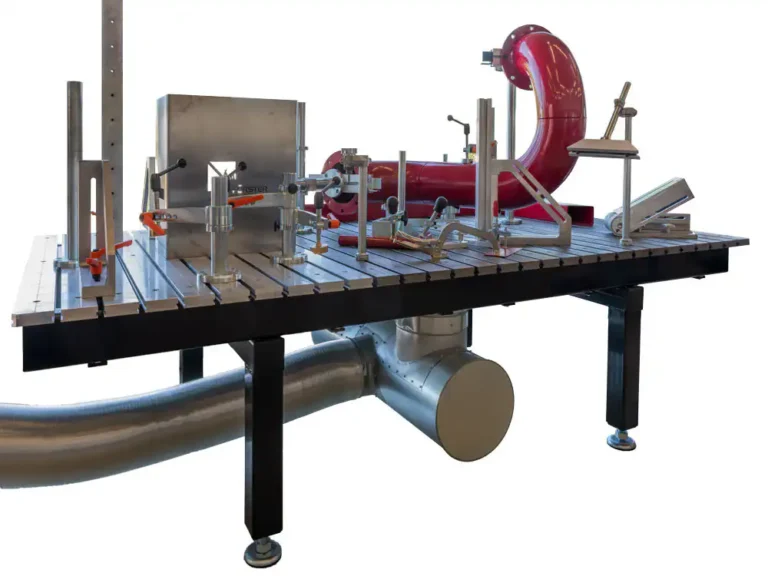

smoke extraction

The extraction of welding fumes is always a complex challenge.

The user often does not accept the need to constantly carry an extraction hose with him to the weld seam.

FÖRSTER welding tables with integrated fume extraction enable continuous welding fume extraction through the table surface. Areas of the table surface can be variably switched to the exhaust air flow.

special welding tables

Special welding tables from FÖRSTER make welding work on particularly challenging components easier.

The possibility of variable positioning of the table surface enables work without forced posture. Increased efficiency and ergonomics in the workplace reduce the costs for all welded assemblies.

Our special welding tables are also based on the modular principle and offer all the advantages of our unique table surface.

rotary welding table

A 360° rotation function with easy handling makes it possible to comfortably change the workpiece position and not the working position.

The turntable is equipped with a manual lock to lock the table top.

- tool free adjustment

- point loads up to 1,5 t,

- surface loads up to 3,0 t

- surface flatness +/- 0,05 mm

Request a non-binding quote for Rotary welding table

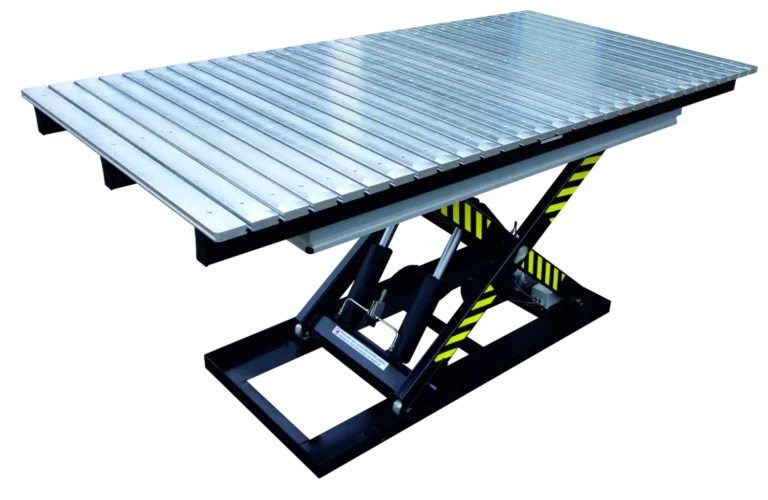

welding table with lift function

FÖRSTER lifting welding tables are equipped with an electro-hydraulic scissor lifting substructure.

An optional undercarriage frame with wheels for easy transport or the variant with height-adjustable feet to compensate for uneven floors also offers maximum flexibility.

- available as stationary on mobile

- point loads up to 1,5 t,

- surface loads up to 3,0 t

- surface flatness +/- 0,05 mm

Request a non-binding quote for welding table with lifting function

welding table with rotary + lift function

A combination of turntable and lifting table for maximum flexibility.

Height-adjustable by means of a hydraulic scissor lift substructure, a rotating function of the table surface and an optional undercarriage frame offer maximum ergonomics when welding.

Request a non-binding quote for Lifting-turning-welding table

Request a non-binding quote for Lift-tilt welding table

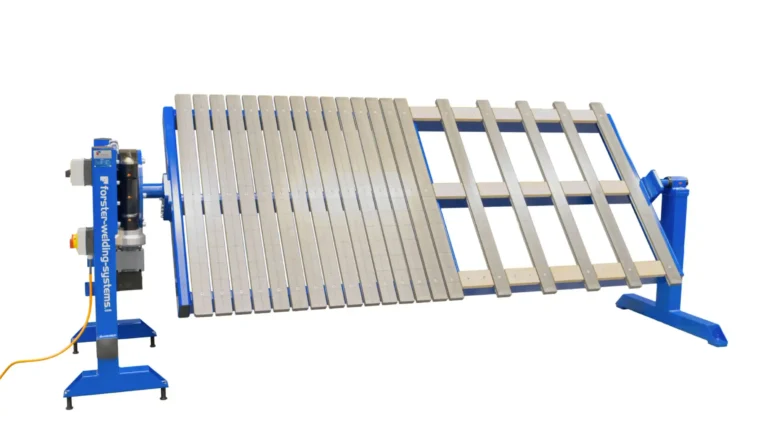

welding table with turn-arround function

FÖRSTER reversible welding tables are equipped with an electromotive rotary drive which enables stepless 360° positioning of the table surface.

All models are partially occupied with 12 rails as standard in order to grant access to the weld seam from all sides.

- For components up to 3000 mm

- 360° rotation function

- Point loads up to 1.5 t

- Area loads up to 1.5 t

- Surface flatness rail +/- 0.05 mm

Request a non-binding offer for turning welding table

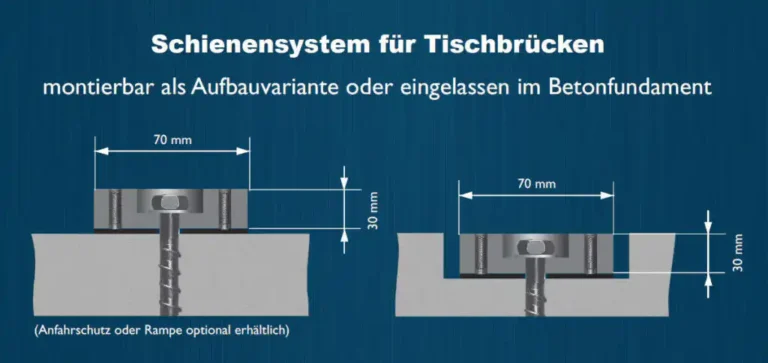

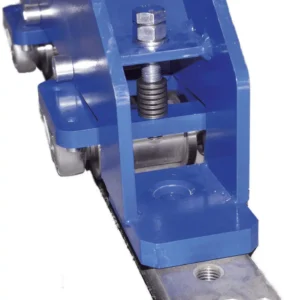

Our floor rail system for mobile table bridges is highly resilient and universally applicable.

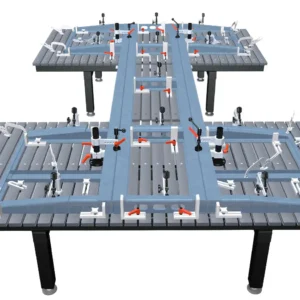

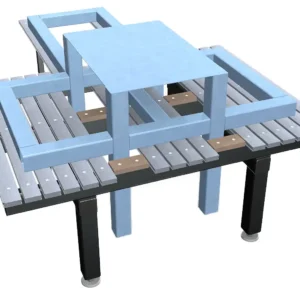

table bridges

Table bridges are the perfect solution for manufacturing length-variable welded constructions.

The table bridges can be moved on a rail system and can be lifted off in a grid of 100 mm.

Due to the portability of the table bridges, the work area can also be variably designed or completely cleared.

Our rail system is designed for installation in or on concrete and can be made in any length and width.