FÖRSTER welding fixtures increase your efficiency, increase the quality of your products and relieve your staff.

Whatever your welding tasks require, we will build the right device for you.

Highest quality, Made in Germany!

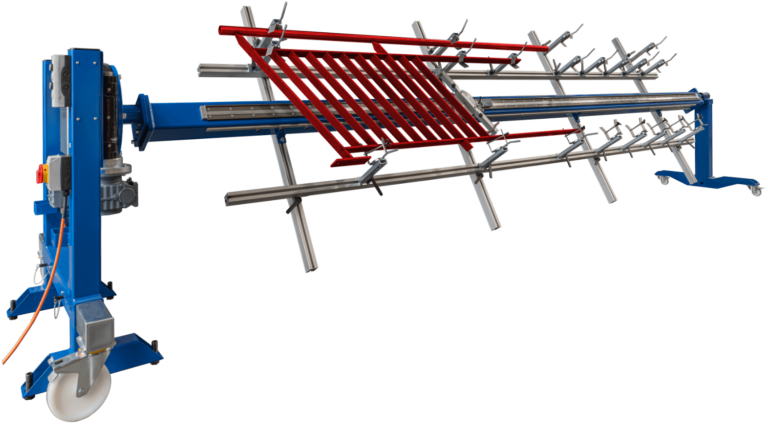

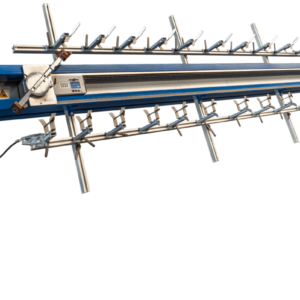

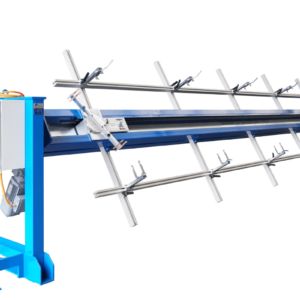

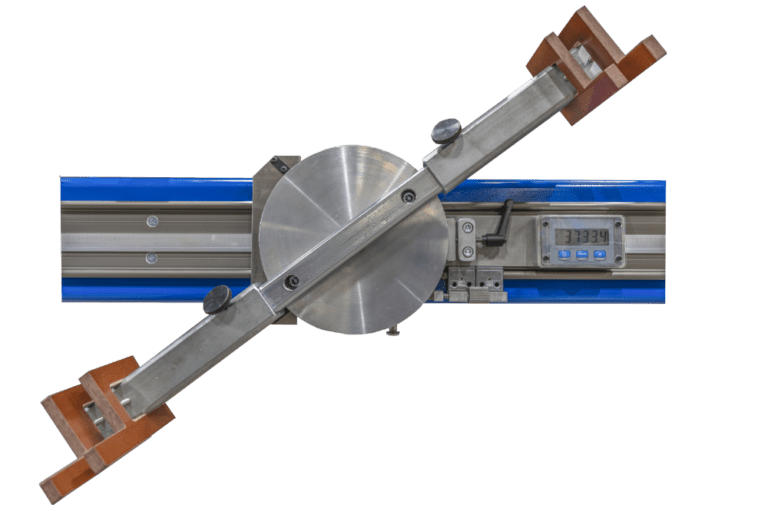

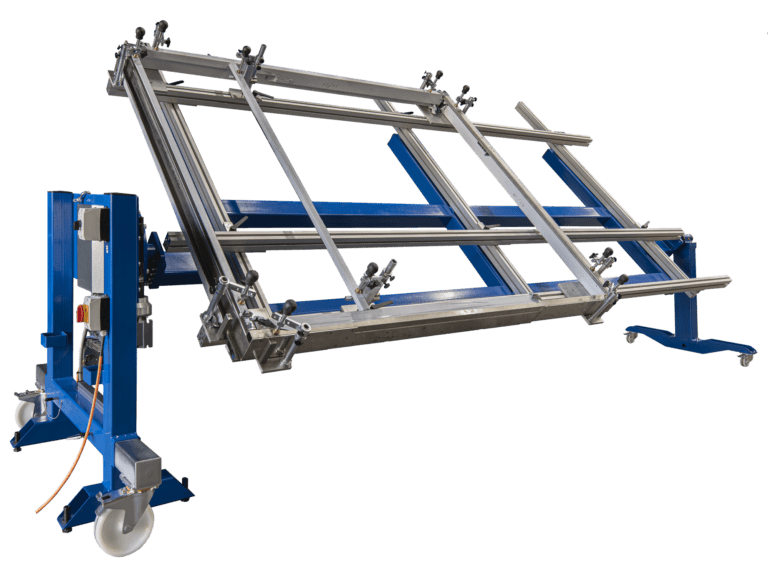

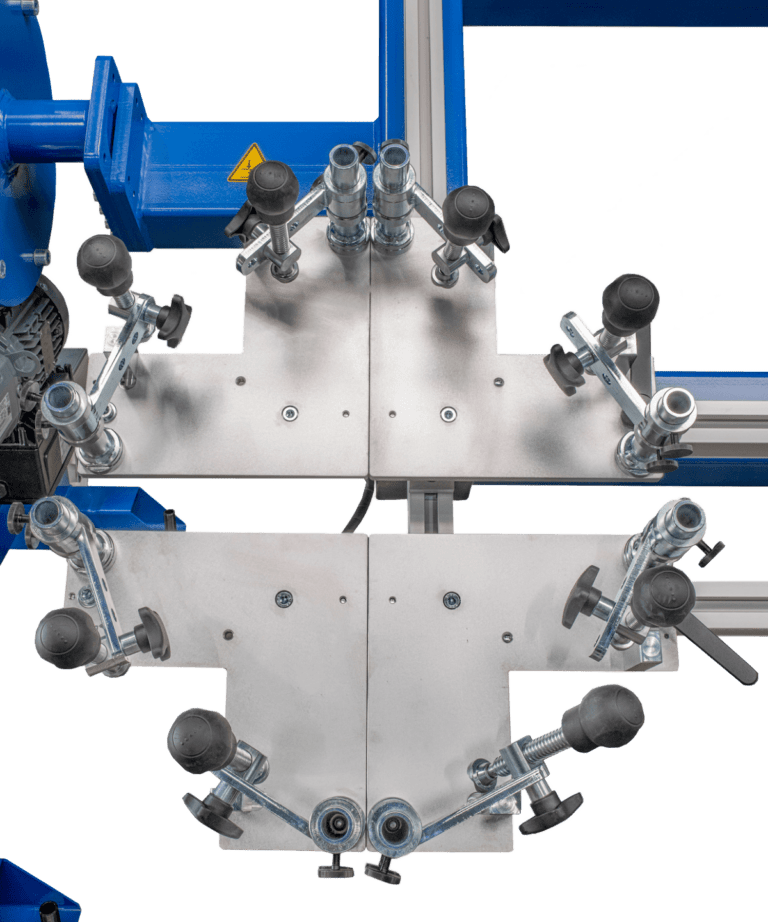

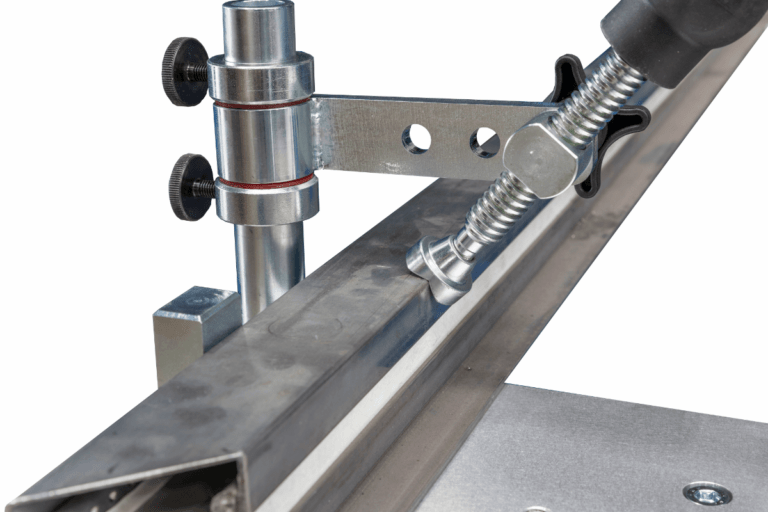

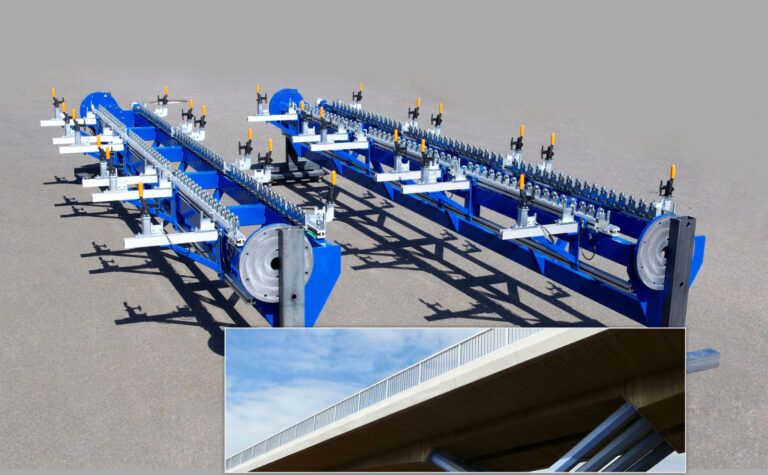

welding fixtures for railings

With maximum variability – effectively manufacture railings

Our in-house development, which has been awarded the Bavarian State Prize, enables you to manufacture railings or similar constructions in half the time.

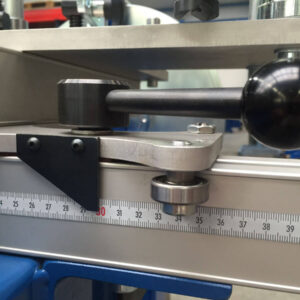

The device is fully adaptable to the railing layout, offers access to the welds from both sides and guarantees full repeatability of the railings.

Up to 50 % time saving with the fixtures form FOERSTER welding systems.

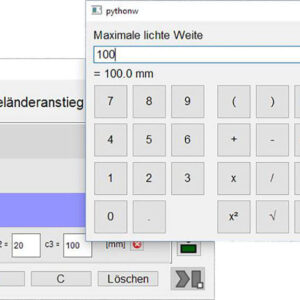

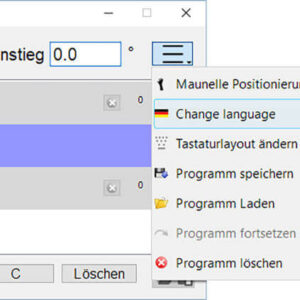

Request a quote for programmable railing fixture

Request a non-binding quote for manual railing fixture

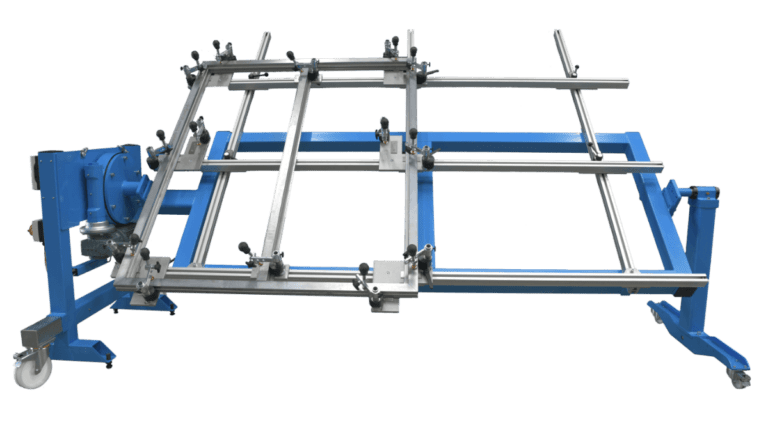

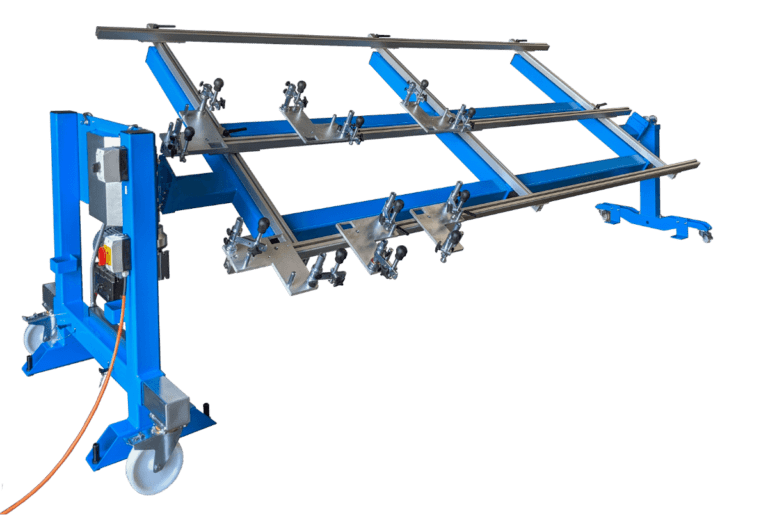

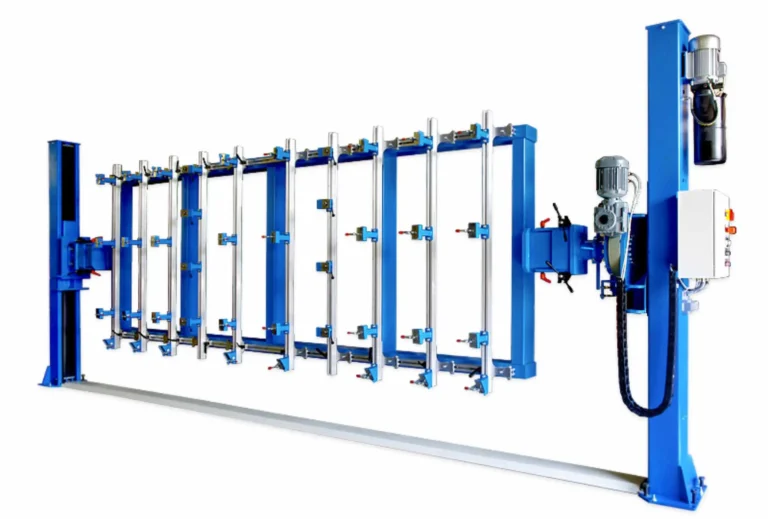

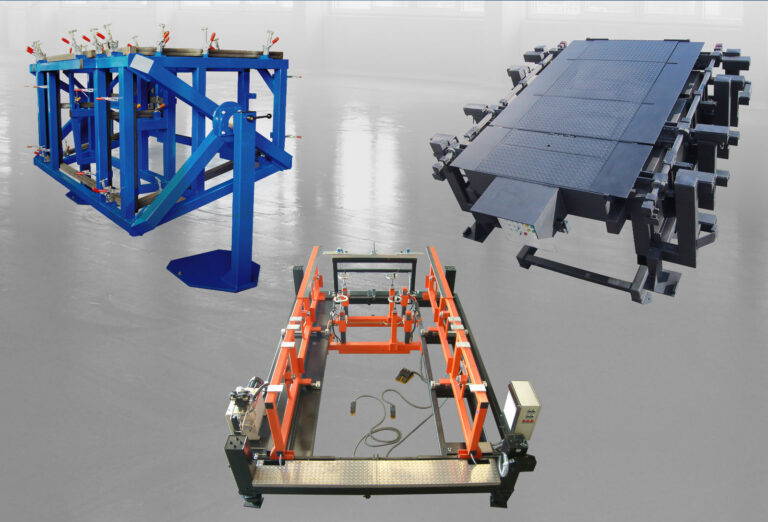

welding fixtures for frames

Welding in one clamping: ergonomic, precise and fast

With a frame welding device from FÖRSTER, you can weld different sizes and designs – without measuring and positioning – exactly at right angles and semi-automatically.

- mobile

- rotatable 360°

- Component weight up to 300 kg

Request a non-binding quote for frame fixture

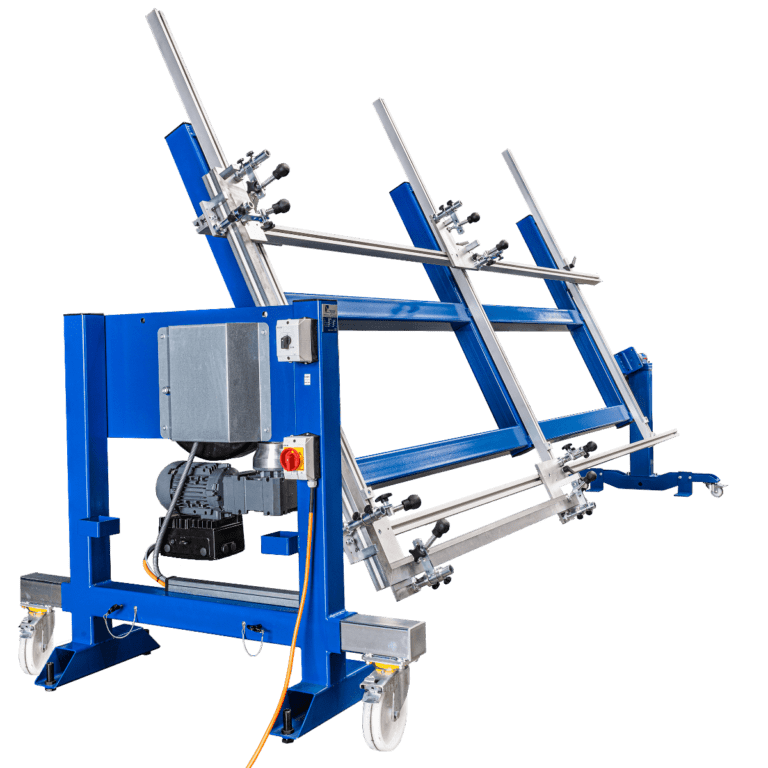

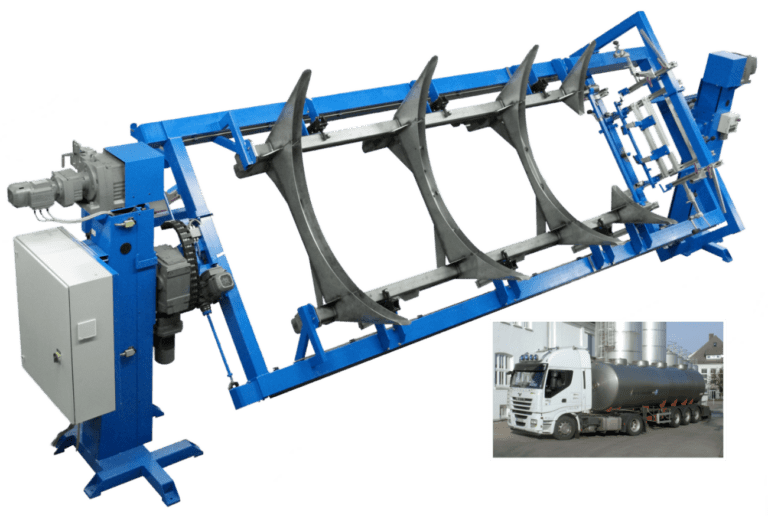

fixture for frames with lift + turn function

Our lifting and turning device offers maximum work simplification for the all-round welding of very large or complex assemblies.

Lifting columns with electro-hydraulic height adjustment form the basis for a comfortable and ergonomic workplace.

We adapt the frame construction to the workpiece to be clamped. Loads of up to several tons and the picking up of very long and wide components are possible.

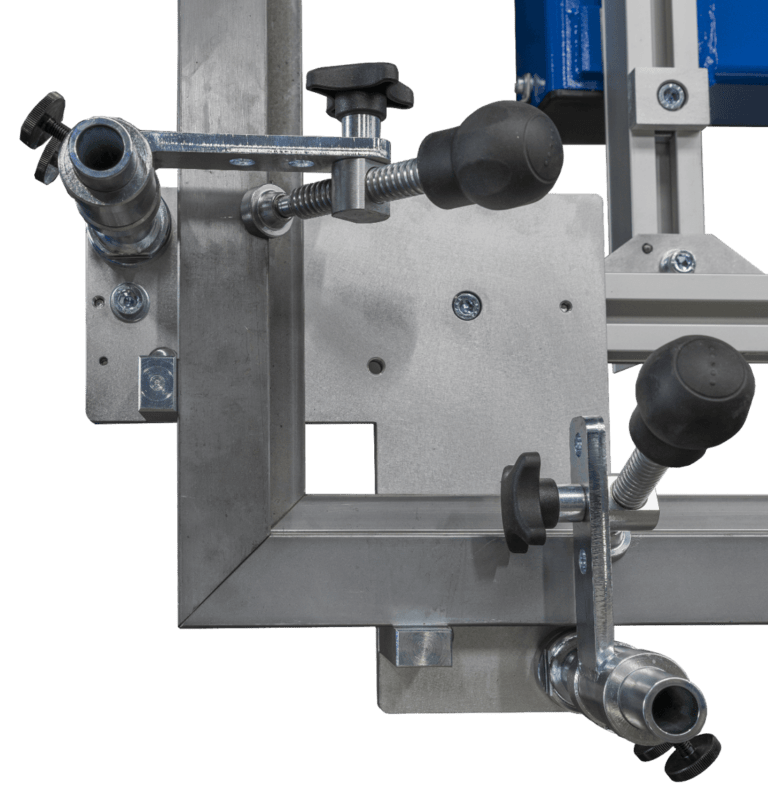

By using our moveable X-Pro or double-groove profiles, the support elements and clamping elements can be individually positioned at any time.

Request a non-binding quote for frame fixture

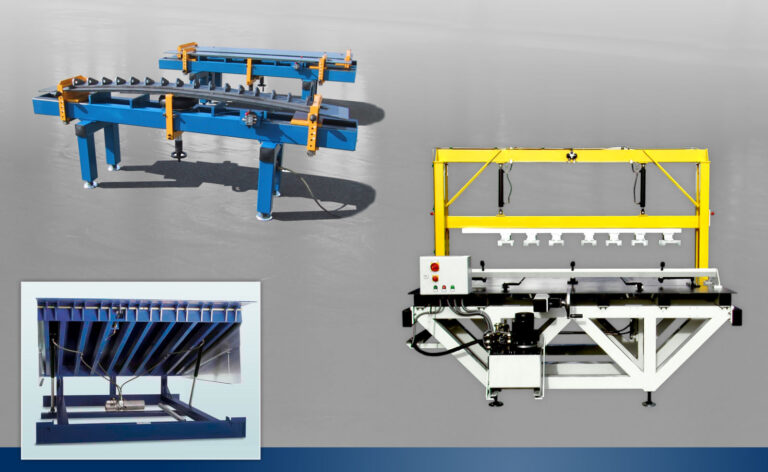

special fixtures

custom made to fit your tasks

For manual and robot welding

The recurring welding of the same or structurally identical components requires the use of fixed or variable welding devices.

A good welding device should not only position the individual parts precisely and safely, but also ensure that as many weld seams as possible can be reached in a suitable welding position without hindrance. Welding distortion that occurs should be limited by targeted prestressing or cooling, whereby the entire welding process must also be taken into account.

High demands on exact component positioning in robotic welding devices should always have priority over corrective seam tracking systems.

Do you have special requests, e.g. heavier loads, larger dimensions or do you need more information? No problem! Contact us here.