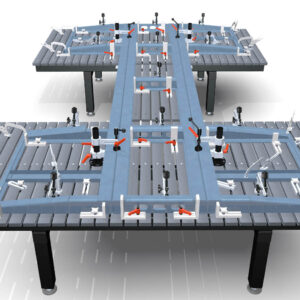

Infinitely variable and secure positioning without grid constraints thanks to the integrated T-slot clamping system.

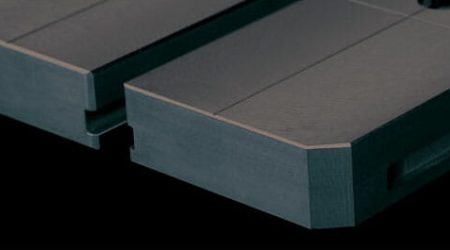

Surface materials with consistent properties over a period of several years, even with rough use.

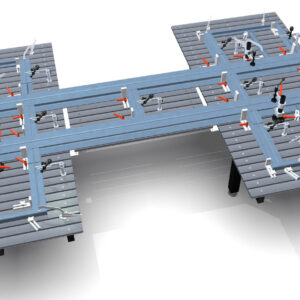

A modular system that stands out due to the variability and versatility of the products.

Three building blocks, connected from the point of view of ergonomics. Highest quality, Made in Germany!

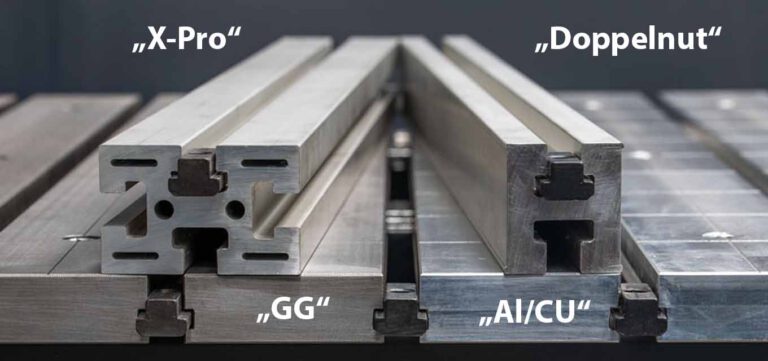

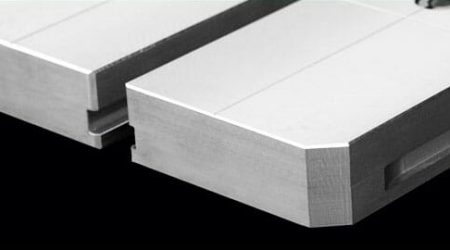

T-slot-system

stepless positioning without a forced grid

With our T-slot system, you can position all clamping elements and stops at any point on the table. You can use it to weld and assemble frames, tubes and housings in any position you want.

The precise setup of the clamping is carried out by infinitely variable displacement of the slings and clamping elements.

Defined engravings in the rails make it easy to count larger distances.

- By using solid material insted of coating, our rails retain their properties for lifetime.

- Gray cast iron ages and with this aging, graphite portions diffuse to the surface, which is expressed in an increasingly gray coloration and thus offers basic protection against weld spatter buildup.

- Applied separating oil penetrates easily into the coarse microstructure of gray cast iron. The open-pored milled surface increasingly prevents weld spatter from adhering.

- Evaporation of the separating oil when weld spatter hits the surface creates a gas bubble and allows the weld spatter, which cools down immediately, to roll off.

- The lower expansion coefficient of gray cast iron compared to steel also minimizes distortion under the influence of heat during welding.

Max. point load single rail: 1.5 t

Gray cast iron ages and with this aging, graphite portions diffuse to the surface, which is expressed in an increasingly gray coloration and thus offers basic protection against weld spatter buildup.

By using solid material insted of coating, our rails retain their properties for lifetime.

Applied separating oil penetrates easily into the coarse microstructure of gray cast iron. The open-pored milled surface increasingly prevents weld spatter from adhering.

Evaporation of the separating oil when weld spatter hits the surface creates a gas bubble and allows the weld spatter, which cools down immediately, to roll off.

The lower expansion coefficient of gray cast iron compared to steel also minimizes distortion under the influence of heat during welding.

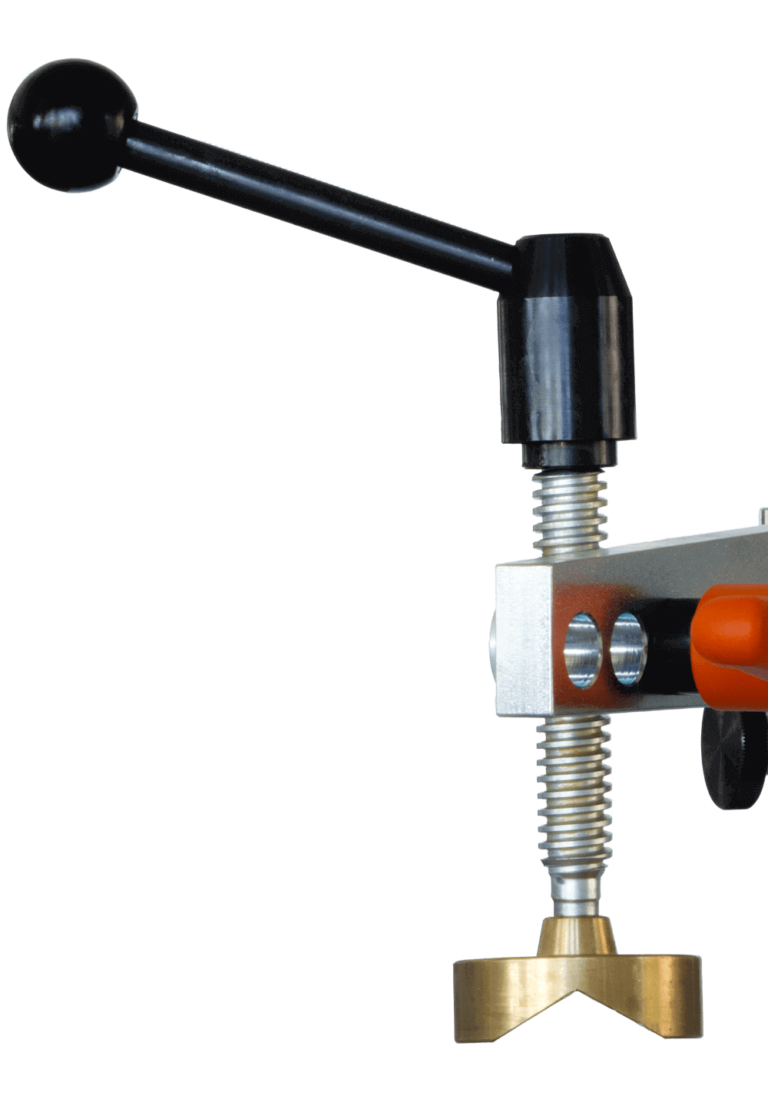

- enables the consistent separation of ferritic materials

- Avoidance of ferritic scratches when processing stainless steel

- high thermal conductivity

- almost complete avoidance of adhering welding spatter

- extremely long service life thanks to modularly exchangeable rails

- universal accessory set for welding stainless steel

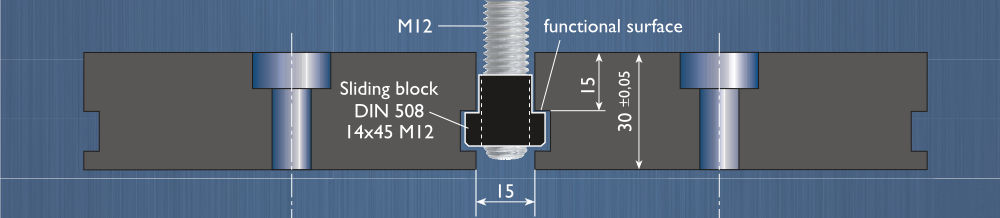

The maximum allowable total load can be increased according to your requirements / grid spacing 100 mm / flatness and angularity H/fine according to ISO 2768T2 / surface flatness +/- 0.05 mm

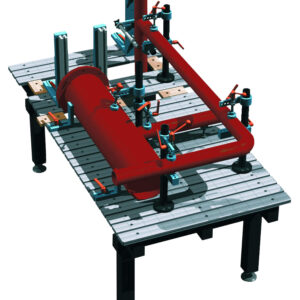

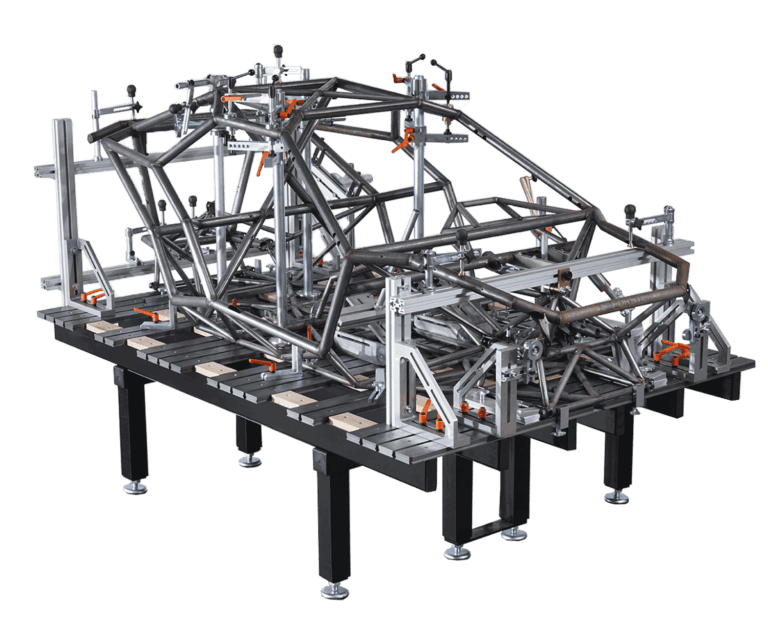

A FOERSTER welding table adapts to your task

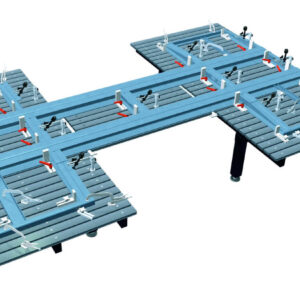

The essential cost factor in the manufacture of a welded assembly is non-productive times. It is therefore worth investing in a variable modular system.

FÖRSTER welding tables consist of individually exchangeable and removable rails for variable surface design.

FÖRSTER welding tables have a modular structure, they can be expanded and are ideal for all types of assembly and welding work.

With our self-developed clamping system and stop elements, you can work precisely, true to size and angle.

Due to the multifunctionality of our building blocks, you have the opportunity to achieve a lot with few accessories.

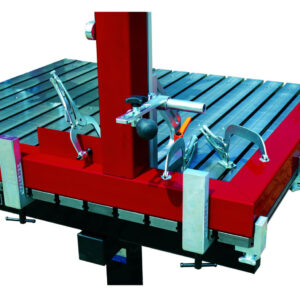

Special accessories

We offer adapted accessories and clamping devices for the processing of stainless steel to match our aluminium-copper bonded rails. The contact surfaces are coated with bronze or made entirely out of bronze and are therefore perfectly suited for the clean processing of sensitive non-ferritic materials.